Webinar Series: The Digitalization of Functional Safety with Added Value

One of the most critical responsibilities of plant operators in the process industry is to ensure that the operation of safety equipment always complies with industry safety standards.

Traditionally, legally compliant functional safety management in process plants requires enormous effort. Today, a new, holistic approach to digitalizing the safety lifecycle is emerging, opening up new potential and helping operators overcome the known challenges in compliance and resource availability.

Particular focus is given to the operational lifecycle phases. Through digitalization, data from the production units are automatically collected and mirrored according to the design constraints. This saves effort and helps identify areas for improvement while the preconditions of the operating license are automatically monitored.

Under the Hashtag #safetygoesdigital, HIMA presents a new approach that supports customers in implementing digitalized functional safety management.

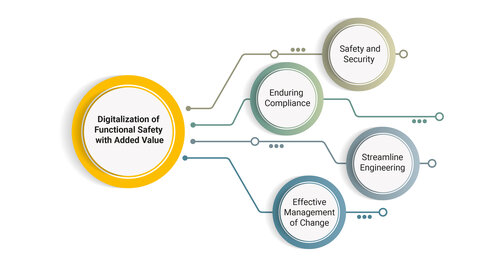

We invite you to join us for our year-long webinar series, dedicated to exploring the pillars of The Digitalization of Functional Safety with Added Value:

1. Safety and Security

-

- 16.04.2024 9:00 am UTC

2. Enduring Compliance

3. Streamline Engineering

4. Effective Management of Change

#safetygoesdigital

The HIMA approach to digitalizing Functional Safety is clear: Digitalization must create added value!

In other words, only digitalize what truly adds value to your operations. With #safetygoesdigital, you can combine safety and efficiency to ensure compliance, reduce costs, and increase plant availability. sponsibilities of plant operators in the process industry is to ensure that the operation of safety equipment

Safety and security are inextricably linked. Technologically, however, these areas must be strictly separated from each other. HIMA achieves this with the "Security Environment for Functional Safety", which maintains security throughout the entire life cycle of the safety solutions. This reduces complexity and lowers investment and operating costs.

Learn more about the "Security Environment for Functional Safety" and how this contributes to the safe and effective operations of safety systems at process plants in our online course. The Webinar will go through the below focus areas:

- Configurations, ready for secure lifecycle support

- Design constraints for safety and security

- Utilization of product features driving security

- Impact of security features on safe operations

- The guiding Principles of coordinating safety and security acc. IEC TR 63069

HIMA digitalization solutions support permanent compliance with standards and regulations by automatically transforming safety-relevant data into usable information. This helps to ensure compliance with the norms and standards that are vitally important for functional safety. Thus leading to increased empowerment for driving a continuous improvement process for functional safety. Such improvement will lead to reduced cost while achieving higher productivity.

HIMA Safety Engineering solutions support seamless data integration, from risk analysis throughout the engineering process to maintenance and retesting:

- Documenting all decisions

- Creation and implementation of detailed engineering

- Use of automatic test programs

- Creation of plant documentation meeting functional safety requirements

HIMA Safety Engineering reduces operating costs and increases plant availability and efficiency.

HIMA solutions enable more efficient processes in the following areas:

- Review of existing asset inventory (hardware and software).

- Detailed identification of changes

- Verification of changes

- Automated testing at the device level

- Review of the design basis of safety functions

Risks and costs for functional safety are minimized and plant availability is increased.